Automatic label application for cylindrical products in the automotive industry

The intention of production automation is for every stage of manufacturing and assembly to be conducted without human intervention or with minimal human intervention to achieve, among other things, the highest possible quality factors, and economic benefits. The same concerns the automatic label application process. It is a common phenomenon in demanding industries, however, problems with the realisation due to the nature of the product to be labelled are frequently encountered.

Such products are those with round, cylindrical shapes. They require a special approach when it comes to automatic application of a self-adhesive label. Depending on the relationship between the length/width of the label and the diameter of the product at the point of application, the use of additional systems which press the label is necessary.

Labelling cylindrical products – what do you need to know?

As far as the applicability of the solution is concerned it is particularly important to determine:

- whether the product can be rotated around its axis of symmetry during labelling,

- whether it is impossible or exceedingly difficult to do and whether it is achievable at the expense of loss of space and time.

What can be the reasons for the lack of possibility of rotating products?

Above all, it is their excessive size (length), the shape of the whole product or its weight. It is also the characteristics of the whole production process. Sometimes it imposes a top-down continuation of the same automation of product transport as in previous stages. Without the ability to intervene in the position of the item to be labelled.

An example of processes that operate in such way are some production lines in the automotive or household appliances/electronics industry. From a certain stage of the assembly process, an incomplete product is fed into an automated process of supplementary assembly. It is interspersed with testing and parameterisation stations.

The production of various cylindrical car suspension (e.g., shock absorbers, half-shafts) or steering components (e.g., steering rods) in the automotive industry can be carried out in a fully automated way. This is done in sequential operation with the same maximum specified cycle time at each assembly station.

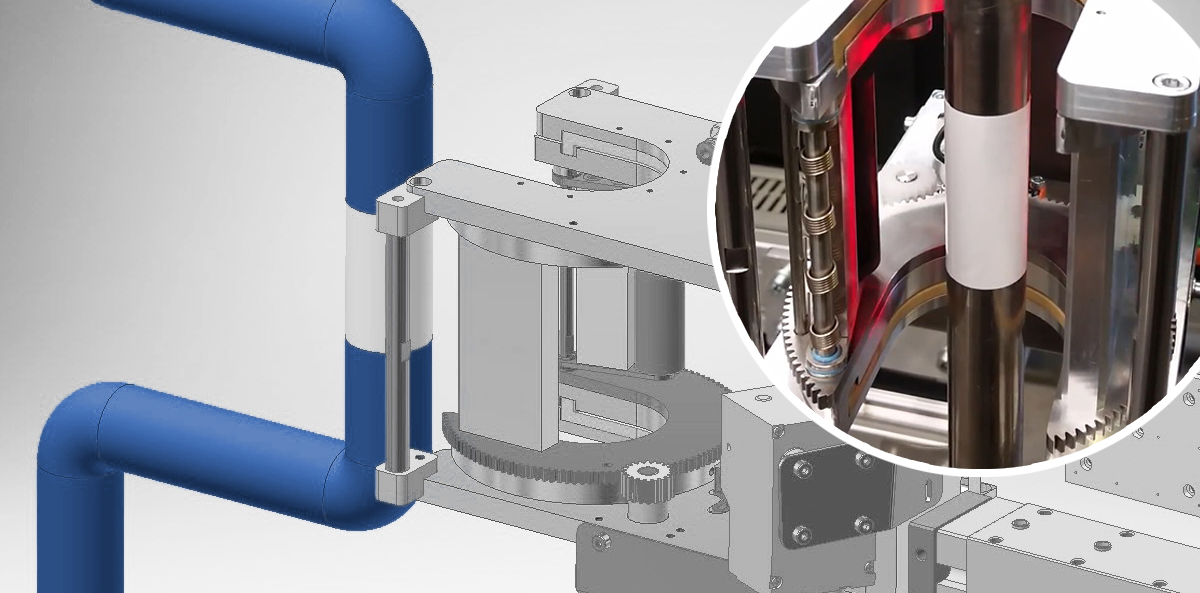

Automatic labelling head

Fully automated labelling of cylindrical and oval products is, of course, feasible. Dedicated labelling heads are then applied. The degree of complexity of the structure of such a head depends on:

- the range of diameters of products which are to be handled

- the above-mentioned length/width of the label with reference to the product diameter, i.e., how tight the label is to be wrapped around the product.

The design and application by Etisoft of an automatic labelling head is an example of such a solution. It can apply and press on a self-adhesive label in the same cycle around a non-moving product with a cylindrical shape.

The head without mechanical changeover can handle products with a diameter from 20 to 40 mm, with servo-controlled speed being increased for smaller diameters and long labels. The stated range of diameters may be increased or shifted. This, however, requires the solution to be redesigned so that it can meet the customer’s individual production needs. A prerequisite for correct label application in the case of this solution is stable seating of a product in the holders or in the conveying die, and, maintaining repeatable positioning with minimal deviation from the axis of the labelled product.

Labelling before cutting products

The same solution can be applied in stand-alone production stations or on lines that produce e.g., power cables, steel bars, tubes, round profiles etc. In such situations, labelling can take place before products are cut to the required lengths.

An integration with a robotic arm, whose task would be limited to placing or positioning the product in the area of the rotary head, is also not an obstacle.

The cooperation with thermal transfer printers equipped with an applicator port (GPIO) will guarantee the placement of fixed and variable data onto the label. They are intended for the product which is to be labelled. This also concerns RFID-tagged labels.

For inspection purposes an optionally installed scanner or vision system can confirm the correctness of label application or printed data. At the same time, it will archive them e.g., on a company server.

An investment in an automatic head for labelling long cylindrical products can lead to a successful automation process of your whole production line. At the same time, it will increase the quality standard and reduce production costs.

Interested? Contact us!